Joining requires connecting independent pieces of sheet metal to produce a larger structure. Widespread signing up for procedures involve welding, riveting, and screwing / bolting.

In such circumstances, fiber lasers tend to be the greater choice. The thickness in the metal can variety involving 20mm to 40mm, with the most thickness dependant upon the laser’s energy.

Welding is actually a broadly regarded procedure for becoming a member of sheet metal. It entails melting the perimeters of two or more metal parts and letting them to fuse jointly.

Laser chopping is a subtractive manufacturing course of action that utilizes a large-powered and centered laser beam to make precise cuts in sheet metal components.

Through our resources, it is possible to uncover the complexities of Sheet Metal Fabrication and acquire insights into creating top-notch layouts precisely customized for this reducing-edge technologies.

Large quantity of techniques and materials In this article by yourself, fourteen varieties of sheet metal fabrication are outlined.

We have been your manufacturing associate to scale projects to creation. Get entire application administration having a crew who will tailor our abilities to enhance Price tag, amount, and high quality Charge of your creation buy.

The decided on finishing method depends upon the metal products’s supposed use as well as designer’s aesthetic Choices. As an example, a significant-good quality finish can enrich the merchandise’s Visible enchantment and raise its worth. In general, finishing is very important in developing a successful sheet metal fabrication challenge. Deciding on a qualified and professional sheet metal fabricator like Prototek can guarantee the specified end result is essential.

Polishing is a typical mechanical procedure that smooths the surface area of sheet metal and offers it a shiny visual appearance. It consists of working with abrasives and polishing compounds to eliminate imperfections and scratches, which ends up in a easy and glossy surface.

This process is normally utilised so that you can attain straight edges on the sheet of metal which has uneven or rough edges. This machinery employs hand power, hydraulics, electricity, or pneumatics dependant upon the thickness of material and length of the cut needed.

If an MRI is the application, stainless steel and aluminum which are not afflicted by powerful magnetic fields may very well be the fabric of choice.

Metal spinning is ideal for moderate metal plates, like stainless steel, copper, brass, aluminum, and many others. Metal spinning can generate several hollow areas of various designs with out compromising their high-quality. Other sheet metal forming processes like bending and punching might be included into a spinning cycle, making it remarkably adaptable for the two compact batch and large volume creation.

Sawing There are various different types of sawing functions that may be performed to cut substantial parts of tube or sheet.

Usually situations various fabrication techniques can sheet metal fabrication company china be utilized to obtain a similar end result. But the right selection

Danny Tamberelli Then & Now!

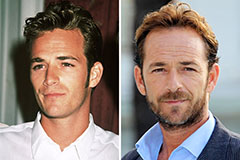

Danny Tamberelli Then & Now! Luke Perry Then & Now!

Luke Perry Then & Now! Andrew McCarthy Then & Now!

Andrew McCarthy Then & Now! McKayla Maroney Then & Now!

McKayla Maroney Then & Now! Ryan Phillippe Then & Now!

Ryan Phillippe Then & Now!